We work closely with our partners to provide you uncoiling, straightening, feeding, punching, profiling, welding, cutting and packaging solutions fully integrated into the automation.

Our turn-key profiling lines are optimized for performance, ergonomy and safety.

STEP BY STEP LINE

Line running step by step: stopping at each punching and/or cutting and offering production speeds up to 20 m/min, depending on the configurations of parts.

Possibility of simple cutting without punching.

CONTINUOUS LINE

Flexible manufacturing systems for light or heavy profiles incorporating the usual functions of unwinding, punching, profiling, cutting and packaging.

Lines adapted for medium or high production volumes, speed of 10 to 80 m/min.

WIDE PROFILES LINES

Profiling lines for wide profiles up to 1500 mm. Possibility of variable width with twin or duplex rollformers.

TUBE LINES

Profiling lines for the manufacture of tubes welded by TIG, High Frequency or LASER.

The dimensions of the tubes can range from ø2.8×0.1 to ø100×3.0 mm.

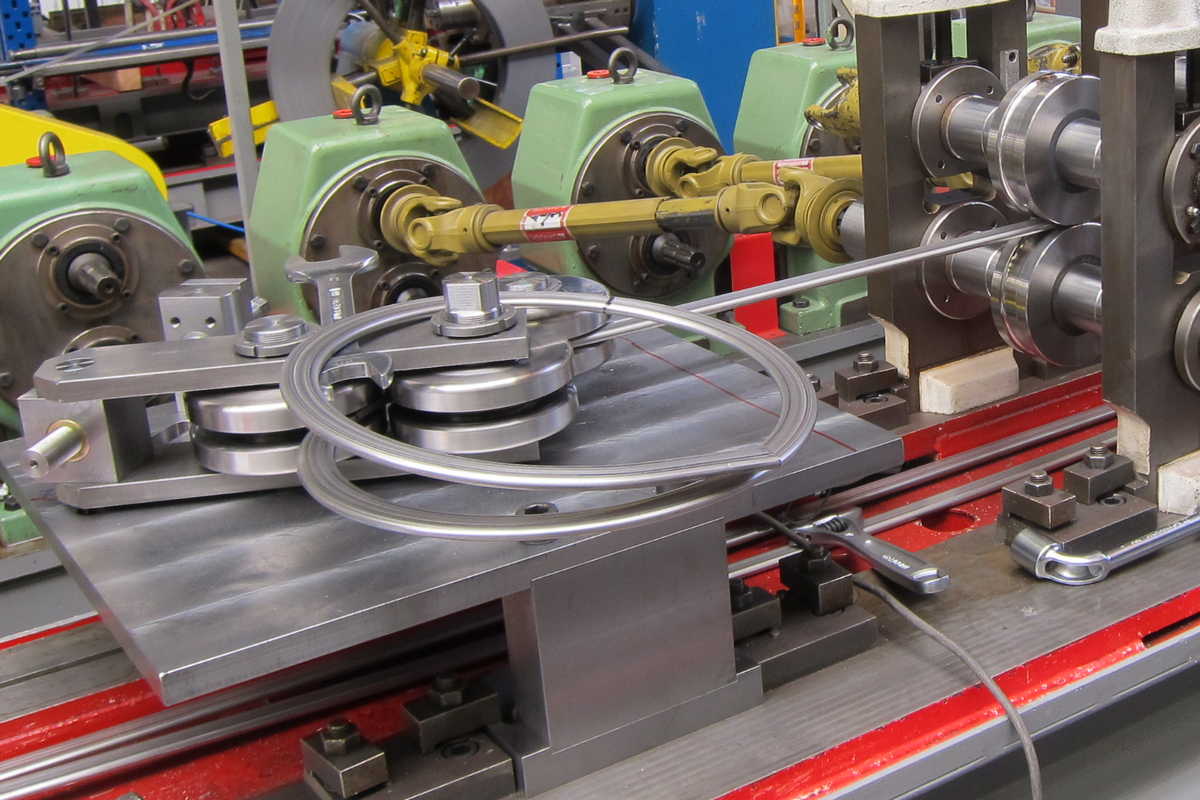

CURVED PROFILE LINE

Manufacture of partial or complete rings at 360°, with round or oval evolutionary radius. Continuous profiling from a coil, without a straight end.

Many applications: tanks, collars, reinforcements…

From the type of parts to be manufactured and the quantities expected, we define together the different components of the profiling line that meet your needs.