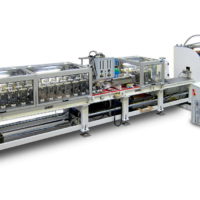

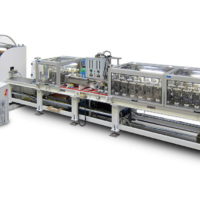

Tube mills for welded tubes by TIG, ERW or LASER.

The dimensions of the tubes can range from ø2.8×0.1 to ø100×3.0 mm.

Line for automotive EGR flat tubes in stainless steel with 2-cathodes TIG welding, combination rollforming tooling, seam welded control by eddy current, dimensional control by on line profilometer.

Line for hydraulic tubes with LASER welding, straightening, bright annealing in-line and flying cut-off with dual blade tool.

Line for aeronautic tubes with 3-cathodes TIG welding, accurate tube sizing, flying cut-off with dual blade tool.

Line for indoor store axis with pre-punching, FIBER LASER welding with seam tracking up to 40 m/min, adhesive tape deposit and flying shear.

Line for welded fence posts with coil-joiner, flat punching and embossing, rollforming with cassettes, High Frequency Induction Welding, cooling, sizing and flying cut-off.